Inventory management is crucial for businesses that handle physical products. It involves monitoring, tracking, and controlling inventory, including production components and finished goods. Maintaining optimal inventory levels is important for smooth operations. Too much inventory raises costs, while too little can lead to out-of-stock situations and customer dissatisfaction.

This article compares the inventory management methods FEFO and FIFO. We will discuss the main differences, benefits, and factors to consider when using these methods, providing insights into their usefulness in different industries and situations. By understanding the variations between FEFO and FIFO, businesses can make informed decisions about their inventory management, improving efficiency, cost-effectiveness, and customer satisfaction.

Effective inventory management plays a vital role in ensuring product availability, controlling costs, and enhancing customer satisfaction. It involves making crucial decisions about which items to ship first and which ones to keep in the warehouse, contributing significantly to a company’s profitability and operational efficiency.

With the advent of digital technology, businesses today utilize sophisticated inventory management systems to track and manage their stock levels. These systems provide real-time data, enabling swift responses to changes in demand and facilitating accurate forecasting. This proficiency can prevent both overstocking and out-of-stock situations, thereby promoting smooth warehouse operations and enhancing overall operational efficiency.

Inventory management strategies are crucial for business success, with the three primary strategies being First In, First Out (FIFO), First Expire, First Out (FEFO), and Last In, First Out (LIFO). Each has unique benefits and drawbacks.

FIFO, where the oldest items in the inventory are sold first, is beneficial for industries dealing with non-perishable goods like electronics, furniture, clothing, and machinery. These goods typically have a long shelf life and minimal risk of spoilage, making FIFO an optimal solution.

FEFO, on the other hand, prioritizes inventory items based on their expiration dates, ensuring the items closest to their expiry date are sold first. This strategy reduces the chance of goods becoming expired products, thereby minimizing stock loss. This method is most suited for industries dealing with perishable goods like food and beverages, pharmaceuticals, and cosmetics, where maintaining product quality is paramount.

LIFO, where the most recent inventory items are sold first, can be useful in certain tax situations. However, it carries the risk of older inventory becoming obsolete or ending up as dead stock, particularly in fast-changing industries.

The choice between FEFO and FIFO is influenced by the nature of the goods being sold. Industries that handle perishable goods, particularly in the food industry, often prefer the FEFO method. This approach prioritizes the sale of items based on their expiration or expiry dates. By utilizing FEFO, businesses can ensure product quality and minimize losses due to spoilage. This method helps maintain freshness and prevents the sale of expired goods, contributing to customer satisfaction and reducing waste.

Industries dealing with non-perishable goods, like electronics or clothing, usually use the FIFO method. This means that goods are sold based on their arrival into the inventory. FIFO assumes that the first items to arrive are the first to be sold. It’s good for products with longer shelf lives that don’t expire quickly. By using FIFO, businesses can manage inventory turnover, reduce the risk of obsolescence, and maintain a balanced stock rotation.

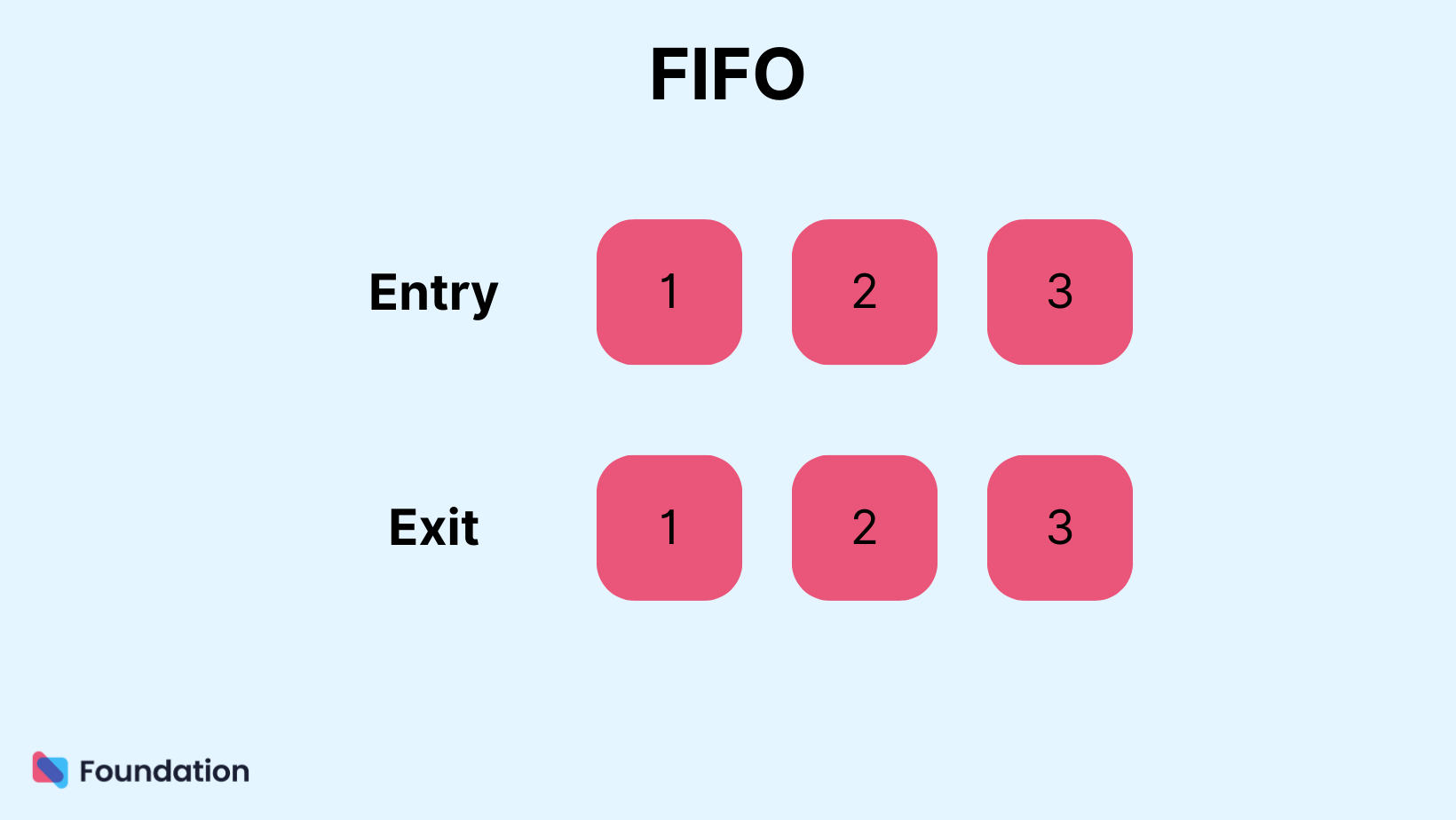

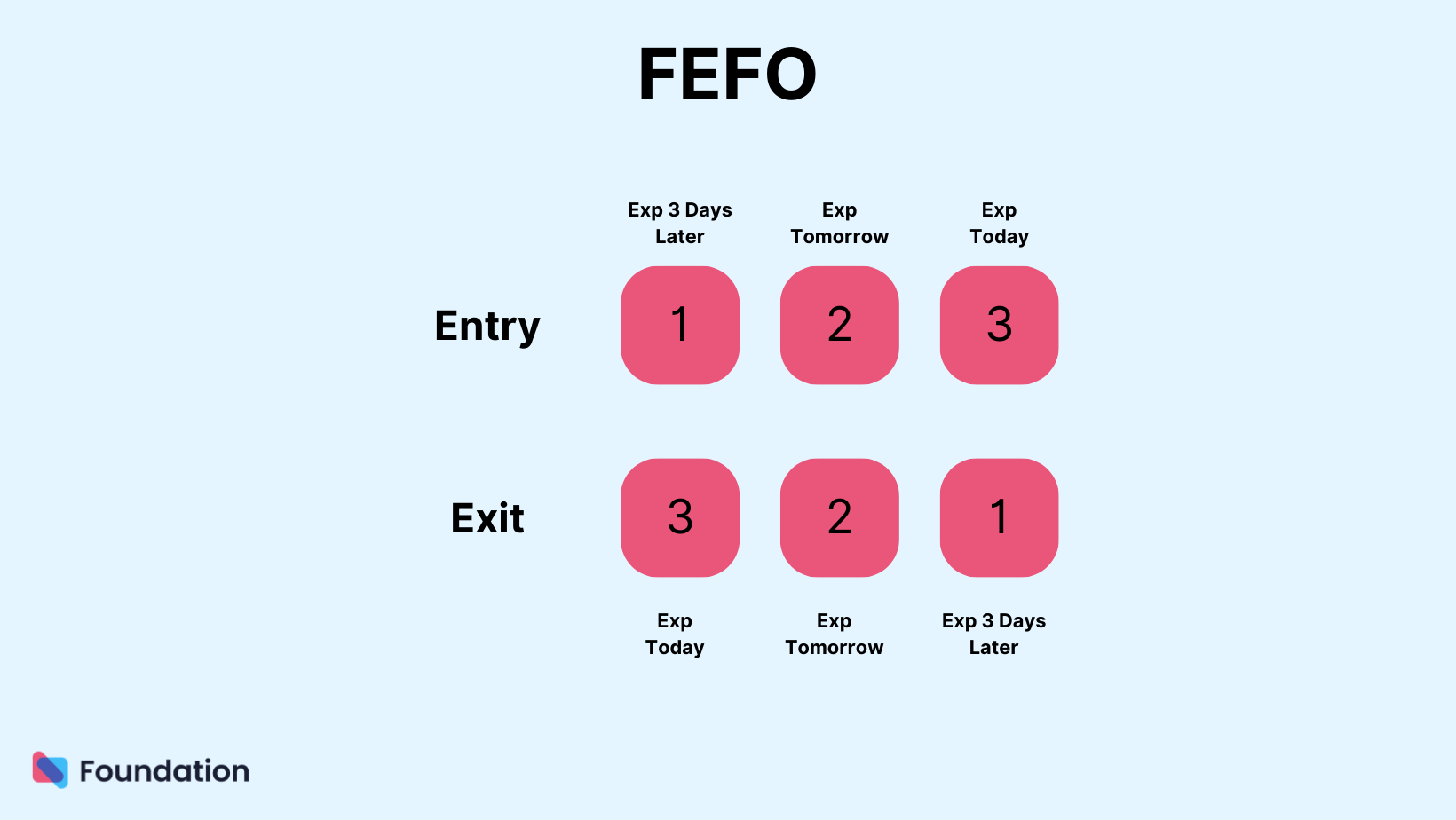

In summery, here is what it will look like:

FEFO (First Expired, First Out):

FIFO (First In, First Out):

FIFO, or “First In, First Out,” is a popular inventory management method. As the name implies, FIFO involves selling the oldest items in the inventory first. This strategy is particularly effective for non-perishable goods or items with a long shelf life. FIFO reduces the risk of inventory becoming obsolete, thereby minimizing wastage and cost. However, it may not be ideal for perishable goods with a short shelf life.

Industries dealing with non-perishable goods often employ the FIFO method. For instance, businesses in the electronics, furniture, clothing, and machinery sectors prefer this approach, as these goods generally have a long shelf life, and the risk of spoilage is minimal.

FEFO, or “First Expire, First Out,” is another commonly used inventory management strategy. Unlike FIFO, FEFO prioritizes inventory based on their expiration dates. It ensures that products closest to their expiration date are sold first, reducing the chance of items spoiling while in storage.

FEFO method effectively manages perishable goods by prioritizing sales based on expiration dates. This reduces the risk of selling expired goods and ensures product freshness. It is particularly useful for industries dealing with perishable goods, such as the food industry, where maintaining quality and minimizing spoilage is crucial.

Implementing the FEFO method requires an efficient system to track expiration dates, increasing operational complexity. Businesses need robust inventory management and technology infrastructure to track and trace expiration dates effectively. Before opting for FEFO, businesses should assess their ability to implement and maintain a system based on their resources and operational capabilities.

The FEFO strategy is most beneficial for industries dealing with perishable items. For instance, businesses in the food and beverage, pharmaceuticals, and cosmetics industries often use this method. In these sectors, maintaining product quality and minimizing losses due to spoilage is paramount.

“LIFO” or “Last In, First Out” is an inventory strategy where the most recent items are sold first. This approach is preferred for non-perishable goods and in certain tax situations since it ensures that new inventory is sold before it becomes outdated. However, there is a risk of older inventory becoming obsolete, which can be managed by selling older inventory first or offering discounts to encourage the sale of older items.

During inflation, LIFO lowers taxes by increasing COGS and reducing taxable income. However, older stock might remain unsold for long. To avoid obsolescence, companies need to sell old inventory before introducing new marketing strategies and offering promotions.

Overall, while LIFO can offer advantages in certain situations, it is important for companies to carefully consider the risks and potential drawbacks of this strategy. By taking a proactive approach to inventory management, companies can maximize their profits while minimizing the risk of obsolete inventory.

The LIFO method can be useful in industries where products don’t risk becoming obsolete over time. Examples include the raw materials industry and certain segments of the manufacturing sector. However, businesses in fast-moving sectors like technology or fashion might not find this approach beneficial due to the rapid obsolescence of their products.

Stock rotation is a fundamental aspect of inventory management, vital for preventing the accumulation of obsolete or dead stock. This practice helps free up valuable warehouse space and ensures customers receive top quality products. The choice of stock rotation method, such as FIFO, FEFO, or LIFO, significantly influences inventory valuation, determining the monetary value of goods held by a company. Taking into account the purchase price of these goods, the selected method impacts the cost of goods sold (COGS), consequently affecting profit margins.

Obsolete inventory refers to items that have become outdated, unsellable, or irrelevant. It ties up capital and occupies valuable warehouse space, thereby reducing a business’s operational efficiency. Strategies like FIFO, FEFO, and LIFO can help manage and reduce obsolete inventory levels, freeing up resources for more profitable use.

A well-executed inventory management system can significantly enhance customer satisfaction. By ensuring product availability and timely delivery, businesses can build a loyal customer base. Moreover, for businesses dealing with perishable goods, effective inventory management practices like FIFO or FEFO can help maintain product quality, thereby bolstering customer trust and satisfaction.

Efficient picking methods, such as batch picking, zone picking, and wave picking, combined with inventory management strategies, play a crucial role in maintaining efficient warehouse operations.

These methods help streamline the process of locating and retrieving items, leading to accurate and timely order fulfillment.

Moreover, proper inventory management optimizes the utilization of storage space, minimizes handling costs, and facilitates smoother operations. By ensuring products are easily accessible, it reduces the time taken to fulfill customer orders, ultimately contributing to improved customer satisfaction.

The average cost method is another inventory valuation approach. It assigns an average cost to each item in the inventory, calculated based on the total cost of items and the number of items in stock. This method is especially suitable when individual items are not distinguishable from one another.

Inventory management methods also need to comply with specific accounting standards. For instance, in the United States, the Generally Accepted Accounting Principles (GAAP) provide guidelines for inventory accounting. Internationally, the International Financial Reporting Standards (IFRS) govern how businesses should manage and report their inventory.

Choosing the right inventory management method is a strategic decision for any business. It depends on various factors, including product characteristics, operational needs, and financial objectives. Businesses must carefully consider factors like product shelf life, cost implications, tax impacts, and compliance with accounting standards when selecting their inventory management approach.

The choice of inventory management strategy (FIFO, FEFO, LIFO) has a big impact on a company’s success. By tailoring inventory management to a company’s specific needs, costs can be reduced, service levels improved, and business growth fostered. Properly applying these strategies can make inventory management a critical component of modern business operations, regardless of the product type (perishable or long shelf life).